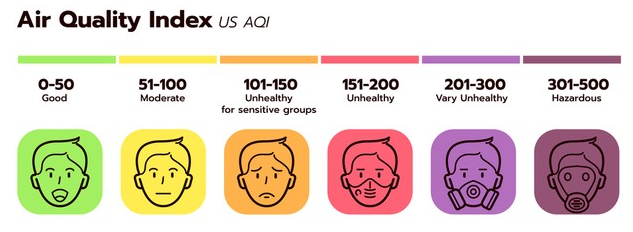

HOW IS THE AIR QUALITY IN YOUR BUSINESS / INDUSTRY ?

AIR QUALITY is defined as:

a measure of the condition of air relative to the requirements of one or more biotic species or to any human need or purpose.

Compressed air is a vital energy source and is utilized in multiple operations, compressed air is regarded as a safe clean utility, as compared to other energy sources.

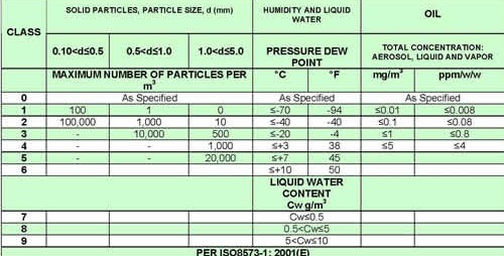

The ISO is a standard when measuring the class of the air. The ISO 8573 air quality standards and ISO 12500 compressed air filter standards make the basis for air treatment product selection much easier.

ISO 8573 is a multi-part standard, with Part 1 classifying contaminant type and assigning air quality levels, and Parts 2 through 9, define testing methods to accurately measure a full range of contaminants.

Air treatment manufacturers present technical data in reference to ISO 8573.1. An easy to understand ISO 8573.1: 2001 table defines the various air quality classes

CONTAMINATION?

Contaminants in compressed air systems have three possible points of origin. They can come from the air drawn into the compressor, from internal compressor functions, and from the compressed air distribution systems.

Water: In total volume, condensed water vapor represents the majority of liquid contamination in a compressed air system. Moisture build up can cause pneumatic machinery failure and promote bacterial growth in the compressed air pipings.

Since compressed air used in food processing operations may come in direct contact with the food, a compressed air dryer producing a sub-zero pressure dew point is required. Dew point, specified as temperature, is the point at which the water vapor held in the compressed air is equal to the compressed air’s capacity to hold water vapor. Desiccant dryers are used to soak up any extra or unwanted moisture. The point of the dryers to to effectively and on an optimum level absorb water vapour to lessen contamination, with this level of dryness bacteria will cease to grow.

Oil is the primate of problems when it comes to contamination of the compressed air. Oil free compressors would be the better option as contamination and growth of bacteria are alot less when it comes to Oil free. Because compressed air may come in direct and indirect contact with food processing, an elevated level of filtration is required.